Laser Tissue Interaction

Last updated: Jan 8, 2021

This project was not possible without the resources provided by my mentor, and friend, Dr. Loris Fichera. Visit COMET Lab for information on his current avenues of research.

During my time at WPI, I worked closely with Dr. Fichera on research regarding the use of a robotic manipulator to guide laser incisions on soft tissue. This documentation provides a brief overview of my work, and I would love to chat about the details.

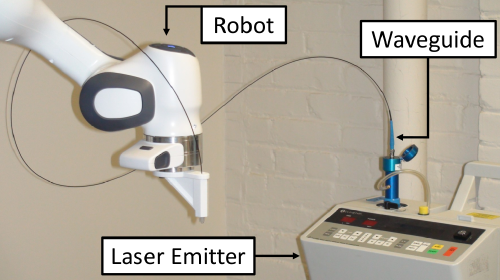

Flexible laser waveguides are used in clinical settings for surgical procedures. The waveguide is held in hand by a surgeon, which requires experience and human guided heuristics to accurately set laser parameters for certain cuts. There is interest in developing a regression model to map laser parameter settings to soft tissue cut depth.

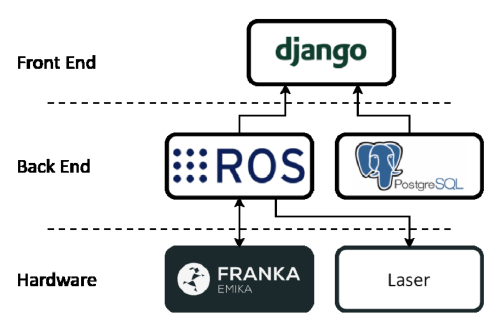

The LTI (Laser Tissue Interaction) software enables non-technical users to operate a robot mounted with a flexible laser waveguide to create and perform repeatable experiments. The software includes CLI (Command Line) interfaces for single cuts at prescribe distances from a calibrated reference point, tele-operation via game-pad, and a controller to follow a generated trajectory. This system accelerates and improves the process of performing laser tissue interactions on multiple pieces of tissue with 0.1 mm accuracy.

Clinical Problem

Laser surgery has been a viable option for surgical staff to use for general cauterization and ablation of soft tissue, especially in cases that require MIS (Minimally Invasive Surgery). However, the learning curve regarding such devices is massive. Hurdles of such systems include the complications of on-boarding a novice user onto a laser system, the practice that is required to qualify said individual, and the non-uniformity of heuristics experienced laser surgeons use.

The Problem: Surgeons often use experience and heuristics to guide laser settings for incision depth

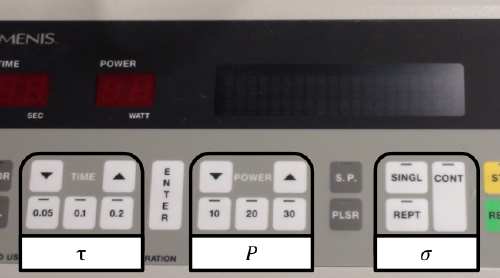

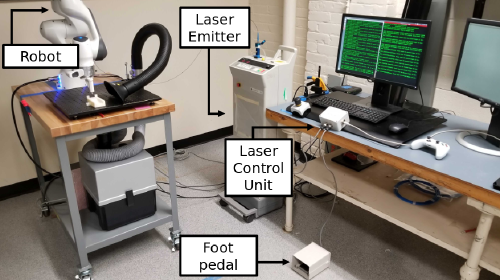

The Lumenis 30C is the laser system COMET labs utilizes for laser ablation. To express the difficulty of operating these lasers, lets analyze the parameters a surgeon would have to manipulate as an example.

The set of parameters {τ, P, σ} have to be adjusted by the utilizing surgeon, with heuristics, in order to obtain the proper settings for a certain application. On top of this, the last parameter σ has three settings that drastically change the behavior of the laser system.

The Solution to reducing parameters and enabling surgeons is to develop a regression model that maps laser parameters to the desired cut a surgeon would produce. My role in this research is to produce software that would make the experimentation on hundreds of soft tissue samples viable. This required a robust controller, an easy interface, and familiar ergonomics while ensuring user safety.

Below I describe the hardware configuration and software developed in order to solve this issue.

Hardware Configuration

The Franka Emika Panda is a 7-DOF serial robotic manipulator (7 jointed arm). The robot is used to direct a flexible laser waveguide in space.

The robot and waveguide works in tandem with a Linux workstation, which enables the custom control loop discussed later, along with repeated degrees of safety such as a laser control unit, which requires both a manual flag from the foot pedal and a software flag to enable the laser emission.

Software

The results of my research was a working CLI inteface that enabled non-technical users to control the robot along with a waveguide to repeat cuts.

After watching the video, you will notice some features of my controller:

- The controller has sub millimeter accuracy

- The controller allows the user to input heights, from a zero-ed distance, at any point in the process

- The controller uses familiar ergonomics, an Xbox One Gamepad, in order to offload technical requirements from the user

- The controller retains its accuracy at any given height, no matter how big or small

Some other features of my controller:

- It minimizes joint movement (Using a secondary task prioritization via Null-space)

- The controller has error management, such as not accepting negative height values and only allowing laser activation once the set point is reached

- The Linux environment has GUI launch options that eliminates CLI interaction for non technical users

Other Approaches

Augmented Reality

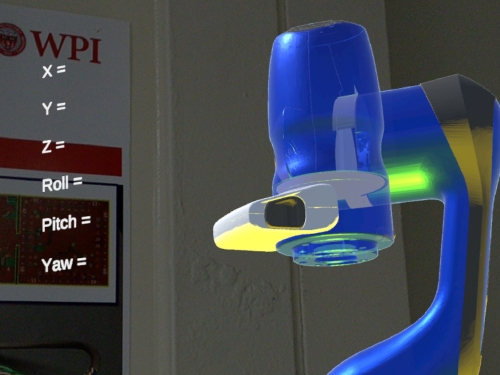

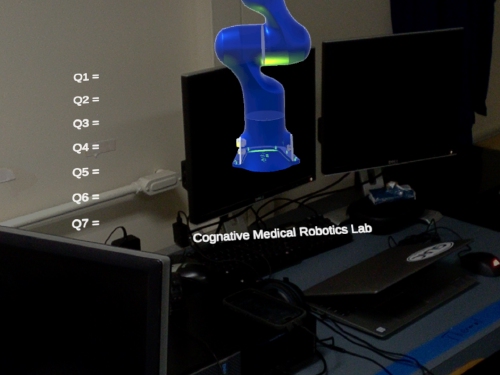

My masters degree involved research on developing an augmented reality approach to surgical laser ablations VIA the Magic Leap One.

Ergonomic Tele-Op

I also developed a robust tele-operation controller for the Panda using a gamepad (connected via Bluetooth).

Front End

I developed a preliminary front end interface for the controller, although this idea was scrapped in order to further investigate controller robustness.

Appendix A: Safety Standards

The following is an excerpt from my safety documentation compiled for COMET lab.

Cooperative Robot standards

The Panda must be installed in a safe environment, where the workspace of the robot is not in reach of the user or any walls. The robot also must be installed on a workbench that is stable enough to handle the robot in any configuration. After these standards are met, the robot will be ready to be connected to the FCI (Franka Control Interface) unit. This unit handles the low level commands for the robot, and also handles the power transmission to the motors.

Assuming all equipment is installed, the robot must then be connected to some sort of tog-gable power source, and the user specified operation button that comes with the Panda robot. These two safety devices ensure that the robot can be stopped whenever harm to itself or a human is imminent or occurring.

A protocol is typically produced by the lab in order to ensure safety. For example (Our typical protocol):

- Two people must be present during operations (One on the button, the other completing the task at hand)

- The robot must be user stopped (user button is pressed) at all times when operation is not expected

- Whenever not utilizing co-operative operations, stand out of reach of the manipulator

Of course, one of the best tool for safety is common sense (I.E. don’t try to reset manipulator objects when the robot is active).

Class 4 laser Safety Standards

Presuming the source code developed will be used for laser cutting with a class 4 laser, one would have to follow certain steps to ensure the safety of all users present when operating the laser.

First, one has to register the class 4 laser. The registration procedure depends on which US state the laser will be operated in.

Second, the medical eye examination of all users that will be present for regular laser use have to be documented. This is done in case there is an accident, and a baseline is needed to measure damage. The screening should include:

- Ocular History

- Visual Acuity

- Macular Function

- Color Vision

- Examination of Ocular Fundus is present

Third, the area that the laser is operated in must be secured in the following ways:

- All windows are blocked with specific laser blocking fabric for the specific type of laser

- There is controlled entry to the laser operating area

- Signage is present for the laser, indicating redundantly that there is a class 4 laser

- An Emergency Shutoff is present for the laser system (I.E. a power switch and footpedal)

- A standard operating procedure is always followed

Damage to a users eye can be prevented in obvious ways, such as:

- Making sure everybody present is anticipating exposure to the laser

- Everybody viewing the laser is wearing compliant laser optics

- Only operators familiar with the equipment are operating the laser emitter

- Other Common Sense protocols: (I.E. - Do not point the laser at your friends eye)

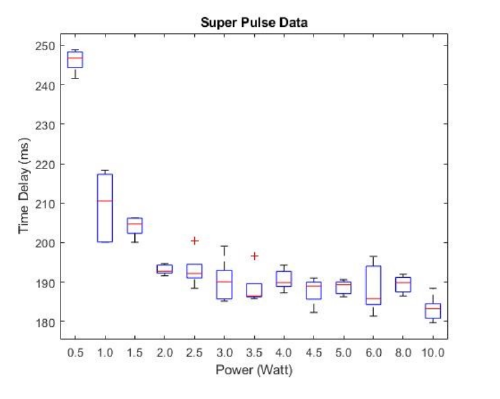

Appendix B: Laser Delay

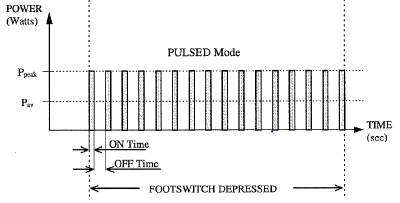

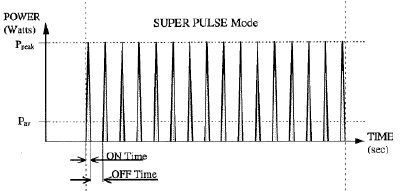

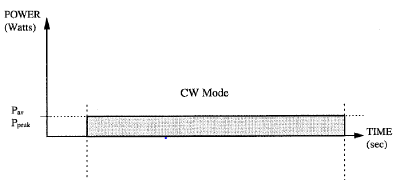

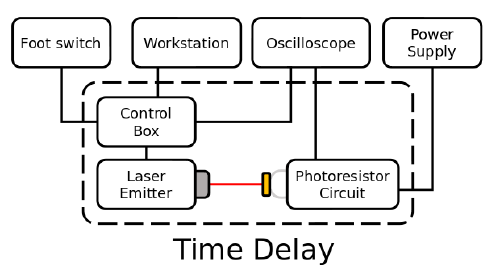

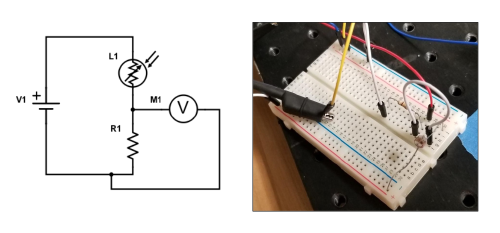

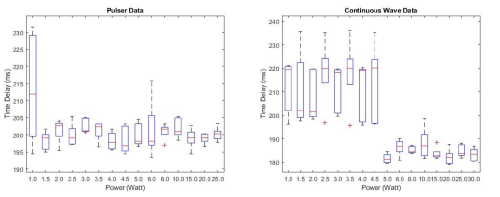

In order to assess the laser time delay, we developed a rudimentary circuit that would allow us to measure the time between the laser control box signal and the received laser pulse. We considered all operating modes while holding power at a fixed interval. Note that for super pulse, power over 10W destroys the sensor used.

Below is the data obtained from the experiment, note that each graph represents a different operating mode of the laser.

The conclusion is that the delay seems to correlate to roughly 0.2 seconds, which depending on the application would either need to be factored in, or could be considered negligible.